Throughout modern industrial operations, machine downtime stands as a formidable foe, capable of halting production lines, draining resources, and denting profitability. While the reasons behind downtime are multifaceted, they often intertwine with a few core issues that challenge even the most meticulously designed systems. Understanding these causes is paramount to crafting effective strategies for sustaining uptime and ensuring the smooth functioning of industrial machinery.

One primary cause of machine downtime lies in equipment failure. Whether due to wear and tear, improper maintenance, or sudden malfunctions, the breakdown of machinery can bring operations to a grinding halt. Furthermore, the complexity of modern machinery exacerbates this issue, as intricate systems are more susceptible to failure without proper oversight and care.

Another significant contributor to downtime is the prevalence of human error. Despite advancements in automation and technological innovation, human factors continue to play a crucial role in industrial operations. From misconfigurations to procedural mistakes, the actions of personnel can inadvertently lead to downtime, highlighting the need for comprehensive training programs and robust error-proofing mechanisms.

However, amidst the challenges posed by machine downtime, there exist proactive measures and solutions aimed at sustaining uptime and optimizing operational efficiency. Implementing predictive maintenance programs leveraging sensor data and predictive analytics can help anticipate equipment failures before they occur, allowing for timely interventions and minimizing unplanned downtime.

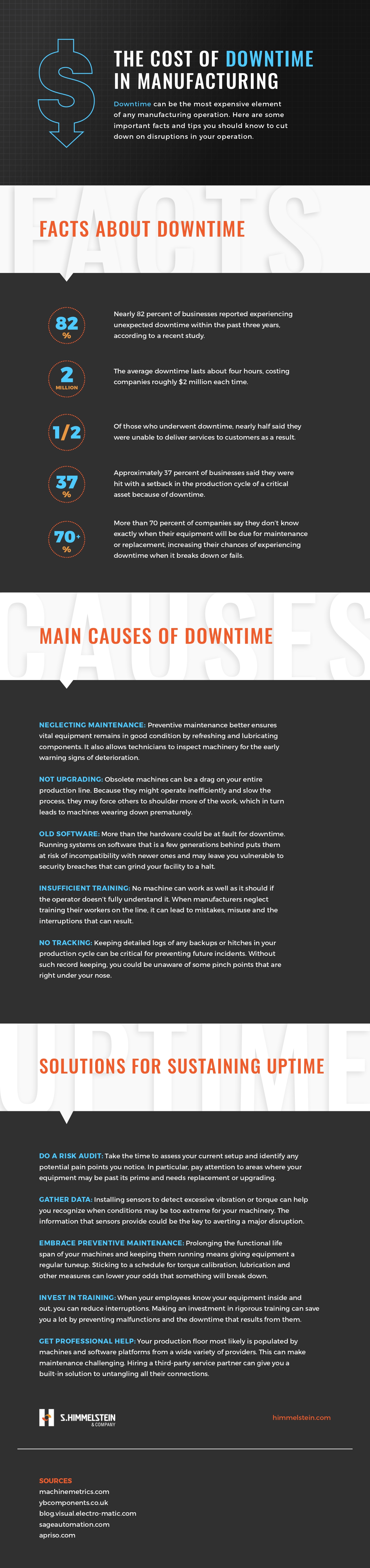

For more on predictive maintenance and other solutions for sustaining uptime, continue reading on to the infographic accompanying this post.

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer